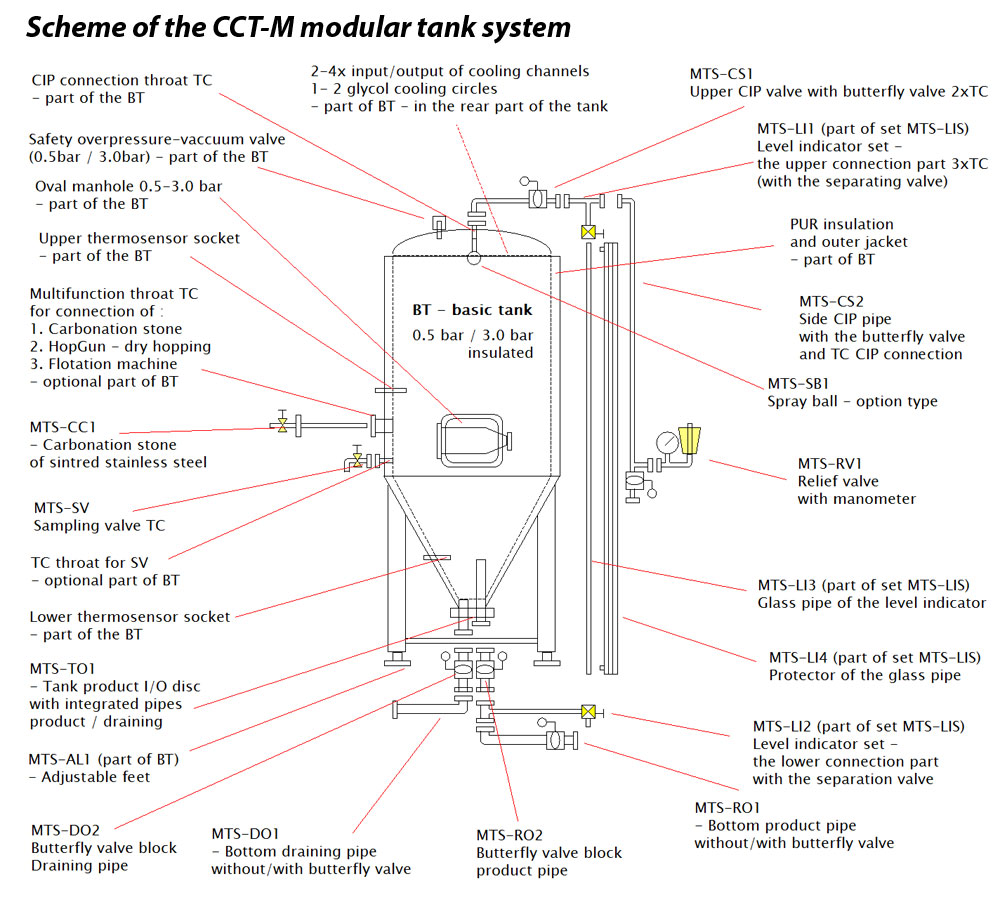

CCT-M Universal cylindrically-conical tanks with a modular construction

CCT-M Modular cylindrically-conical tanks are very versatile products of our production that enable you to assemble a beer tank in a configuration that is just required for the intended purpose. The currently used tank configuration can be changed at any time, even in full operation when the tank is pressurized and filled with an beverage like beer or cider in the middle of their production process.

Description of modular cylindrically-conical tanks CCT-M

Modular cylindrically-conical tanks consist of a base tank (BT) and expansion accessories (valves, fittings, armatures, tools …) By choosing and using various types of expansion accessories, it is possible to assemble the tank in several configurations that are optimal for the desired part of the production process.

Basic tank

The basic tank is a pressure vessel made of stainless steel AISI 304, according to the standards applicable to food production, with a smooth inner surface (surface roughness 2B / 2J is chosen by the customer). The basic tank consists of a cylindrical body, conical bottom, arched top bottom, 3-4 feet and of armatures for connection of optional accessories. We produce them in versions:

Depending on maximum permissible overpressure:

- Non-pressure tank – maximum achievable overpressure 0.5 bar – suitable only for the main fermentation process (beer, cider, wine) and for production of low-pressure beverages (must, wine)

- Pressure tank – maximum available pressure of 3.0 bar – suitable for main fermentation of all carbonizated alcoholic beverages like beer or cider, fermentation and maturation under pressure, carbonization, flotation, finishing and isobaric bottling of beverages into sale packages like glass bottles, PET bottles, steel kegs.

Depending on the quality and surface finishing:

- SQ – standard quality – SB Ra<0.8μm : grinded inner surface of the cylindrical part, SJ Ra<0.5μm : polished inner surface of the conical part. External steel jacketes with all riveted connections and grinded surface.

- HQ – high quality – SJ Ra<0.5μm : polished all internal surfaces, polished welds. External steel jacketes with all welded connections and grinded surface.

- TQ- top quality – SJ Ra<0.5μm : polished all internal surfaces, polished welds. External steel jacketes with all welded connections and polished surface.

According to the insulation and outer jacket:

- Non-insulated tank – equipped with a double jacket with cooling channels, without PUR insulation, without outer jacket (tha tank has to be place it in insulated room chilled by air)

- Isolated tank – equipped with a double jacket with cooling channels, including PUR insulation, including an external stainless steel jacket (for placing in any room)

>> Our offer for standard insulated CCT-M modular basic tanks

Modular tank accessories for equipping of the CCTM tanks

MTA tank expansion armatures – are optional accessories for equipping of the basic tanks. The required configuration of the modular cylindrically-conical tank is reached by equipping the basic tank with appropriate combination of additional armatures.

The most widely used accessories for expansion of the modular cylindrically-conical tanks :

| COMPONENT | POSITION | IMAGE | DESCRIPTION | MORE |

| BT - Basic tank |  |  | Presure tank produced of stainless steel AISI 304 according to European standards for food production equipment. Smooth inner surface (2B/2J) with roughness according tu customer´s requirement. Cylindrical upper part and conical lower part are optimalized to professional beer, cider, or wine production. Two pressure variants: 0.5 bar/3.0 bar, three quality variants: Standard Quality / High Quality / Top Quality. | Descriptions and prices |

| TO1 - Bottom armature with two throats |  |  | Bottom armature with two throats is a disc mounted on the bottom throat of the basic tank . It includes two welded throats with the TriClamp or DIN connection for joining with the RO1, DO1 or RO2, DO2 parts : The pure-product draining pipe and the filling and draining pipe. The pure-product draining pipe may be fixed or segmented for easy setting level its length according to current yeast level in the tank. | Descriptions and prices |

| CS1 - Upper CIP pipe |  |  | The upper CIP armature is intended for the cleaning and sanititing of the tank with sanitizing solutions and also as part of the CO2 in/out pipe. Connected to the SB1 shower head, to the CS2 side CIP pipe and to the LIS filling level indicator. We offer this armature with a flap or without flap. | Descriptions and prices |

| CS2 - Side CIP pipe |  |  | The side CIP armature is intended for the cleaning and sanititing of the tank with sanitizing solutions and also as part of the CO2 in/out pipe. This armature is connected to the CS1 armature or also to the LIS filling level indicator (if is currently used). It is equipped with a flap and ended with a socket TriClamp or DIN coupler for connecting with the sanitation hose from the CIP station. | Descriptions and prices |

| LIS - Filling level indicator |  |  | The filling level indicator allows visual monitoring an actual level of the product in the tank. Recommended to use when the tank is used for the filling beverage into bottles, kegs or cans, for dispensing beverage directly from the tank into glasses or during the filtering or pasteurizing process . The fill level indicators are often required also by custom officers to easy visual control of current alcohol beverage volume in the tank. | Descriptions and prices |

| RV - Pressure adjusting fermentation apparatus |  |  | Pressure adjusting fermentation apparatus with the manometer and the air-lock. This armature is very important equipment to visual control of the fermentation and maturation process during beer, cider or wine production, adjusting required pressure and monitoring of current pressure CO2 in the tank. Joined using the TriClamp or DIN connector to the CS2 armature. | Descriptions and prices |

| RO1-DO1 Filling-draining pipes |  |  | RO1 and DO1 are armatures designed for easy joining of hoses with the TO1 bottom armature with two throats. They may be joined directly to the TO1 armature or also through the RO2, DO2 flaps or to LIS filling level indicator. They are placed under the TO1 armature, according to current configuration of the tank. These armatures may be equipped with the flaps too. | Descriptions and prices |

| RO2-DO2 Filling-draining flaps |  |  | RO2 and DO2 are flap valves that may be connected directly to the TO1 bottom armature as a terminator part or they are placed between TO1 and other parts (RO1, RO2, LIS) according to current configuation of the tank. Available with TriClamp, DIN coupler or in combination of both connection types. | Descriptions and prices |

| SV1 - sample valve |  |  | The sample valve (sample cock) for tasting samples of produced beverage directly from the fermentation tank during the beverage production process. It is connected to the SV port of the basic tank (TriClamp or DIN connection) | Descriptions and prices |

| SB1 - Shower head |  |  | The shower head (spray ball) is an accessory designed to easy cleaning and sanitizing of surfaces inside the tanks using the CIP station and sanitizing solutions. It is joining with the upper pipe using a pin to the CIP port inside the tank. We offer two types of the shower head – the fixed shower head and the shower with rotational head. | Descriptions and prices |

| CC1 - Beverage carbonation candle |  |  | Beverage carbonation candle is the optional accessory for CCT-M fermentors. Its function is carbonation of beverage inside tank. This equipment is often used as final operation during the beer or cider production process before filling beverage into packages. It may be inserted to the basic tank and joined with the tank using the MT multiport (TriClamp or DIN connection). | Descriptions and prices |

| PFH - Beverage hose splitter |  |  | The beverage hose splitter is a special tool to easy filling of pure product (like beer wort , fruit juice) to the fermentation tank. It is pipe hub with, one product input, two product outputs a sight glass and two butterfly valves. This equipment is designed for example for work during filling wort into fermenters after finishing of the wort brewing process. The beverage hose splitter is designed mainly to separation of water and sludges from the pure beverage product during pumping beverage to the fermentation tanks. TriClamp or DIN connections. | Descriptions and prices |

| LAD - Ladder |  |  | The optional accessory of the CCT-M tank : The ladder allows easy access to upper part of the tank – for example to connection and disconnection of the CIP pipes and the fill level indicator. The ladder is safely fixed with the basic tank using the LC hooks welden on the tank. | Descriptions and prices |

>> Our offer : accessories for the CCT-M modular fermentation tanks

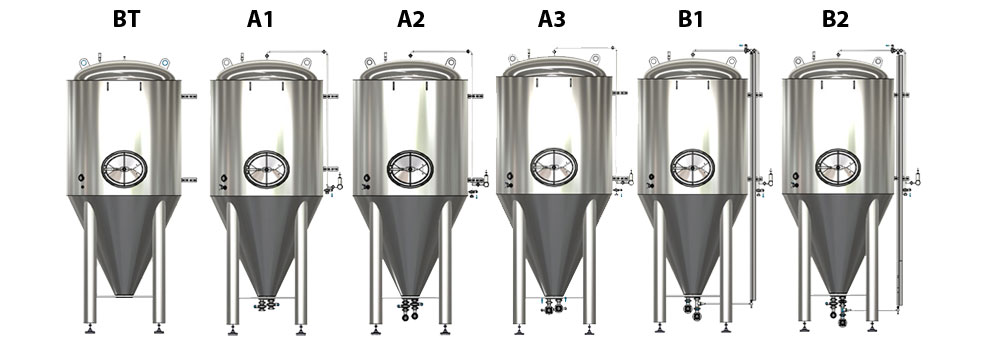

Recommended configurations of modular cylindrically-conical tanks

Modular CCT-M cylindrically-conical tanks can be assembled in a variety of configurations. Here are the most commonly recommended used configurations and a description of their functionality.

Offers for the CCTM modular tanks in all recommended configurations :

-

CCTM-A1 : Offer for the modular tanks CCTM in configuration A1

-

CCTM-A2 : Offer for the modular tanks CCTM in configuration A2

-

CCTM-A3 : Offer for the modular tanks CCTM in configuration A3

-

CCTM-B1 : Offer for the modular tanks CCTM in configuration B1

-

CCTM-B2 : Offer for the modular tanks CCTM in configuration B2