Pressure vessels for the secondary beer fermentation and beer carbonation under pressure

Cylindrical beer maturation tanks : Beer maturation-carbonation tanks, beer conditioning tanks, beer secondary fermentors – Cylindrical pressure vessels for the beer secondary fermentation process – these are the most common names of this type pressure vessels. After end of the beer primary fermentation process the fermented wort (also called green beer or young beer) is pumped from the primary fermentation tanks into the beer maturate tanks, where a secondary fermentation process (natural beer carbonization) under pressure takes place. Then beer is pumped into pressure beer storage tanks, or filled into kegs or bottles.

What is the beer maturation tank intended for ?

The main function of the beer maturate tank is to provide a secondary phase of the beer fermentation – the maturation of beer, which is the natural saturation of the beer by the carbon dioxide which is spontaneously produced during the physical activity of the beer yeasts at low temperature (usually from 1°C to 4°C) and low pressure (usually from 1.0bar to 2.5bar).

The beer maturation tank can also serve as an overpressure tank for special final operations with beer (called also the combi tank / the universal tank), so it is possible to use the tank for the filling beer through into the glasses, to filtering or pasterizing of beer, to change flavor of beer or to isobaric filling beer into bottles or kegs.

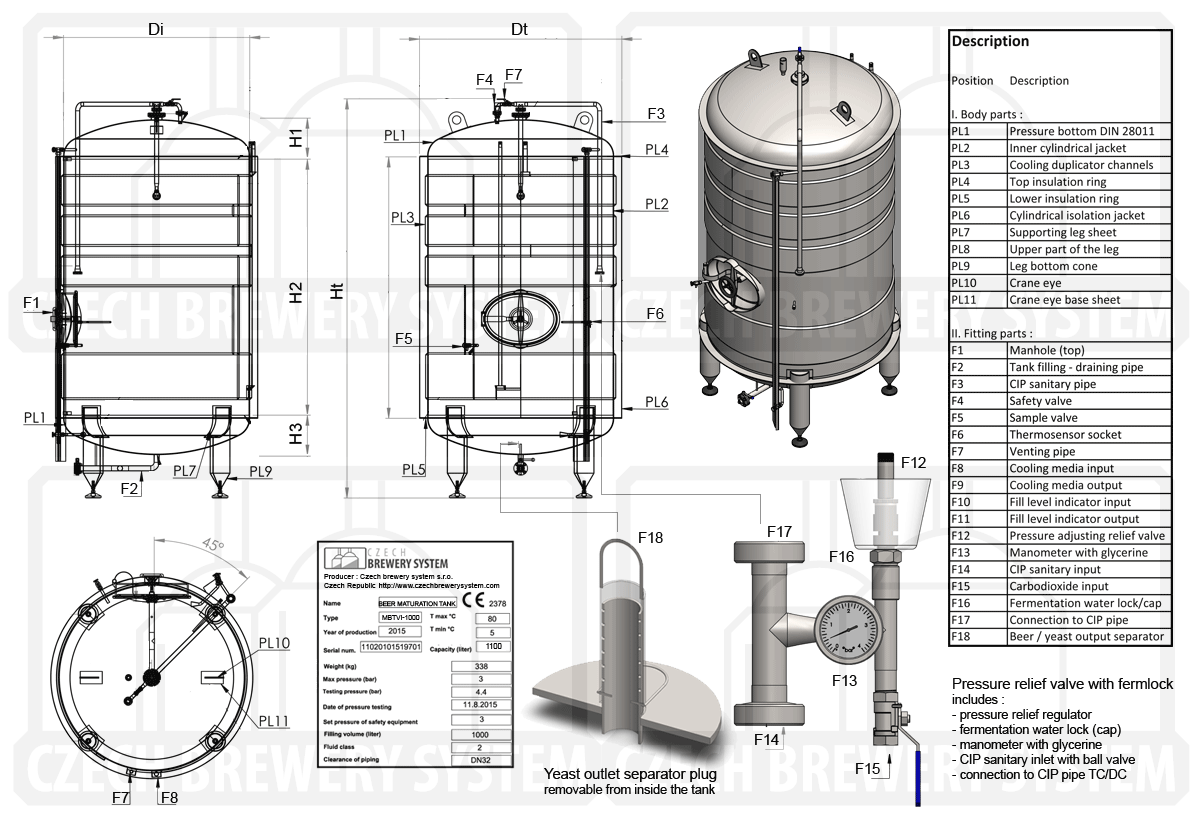

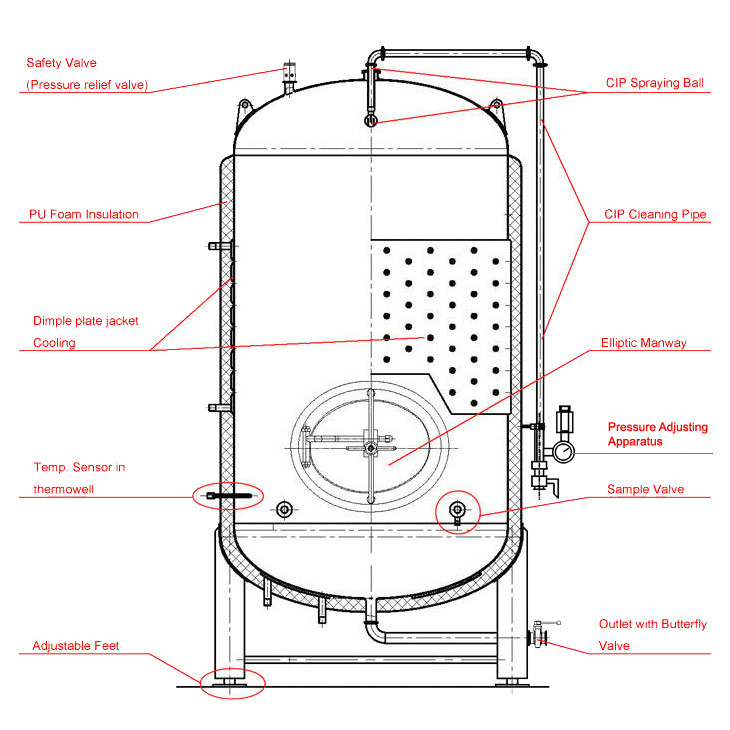

Description of the tank for beer maturation / insulated, vertical, cooled with water or glycol :

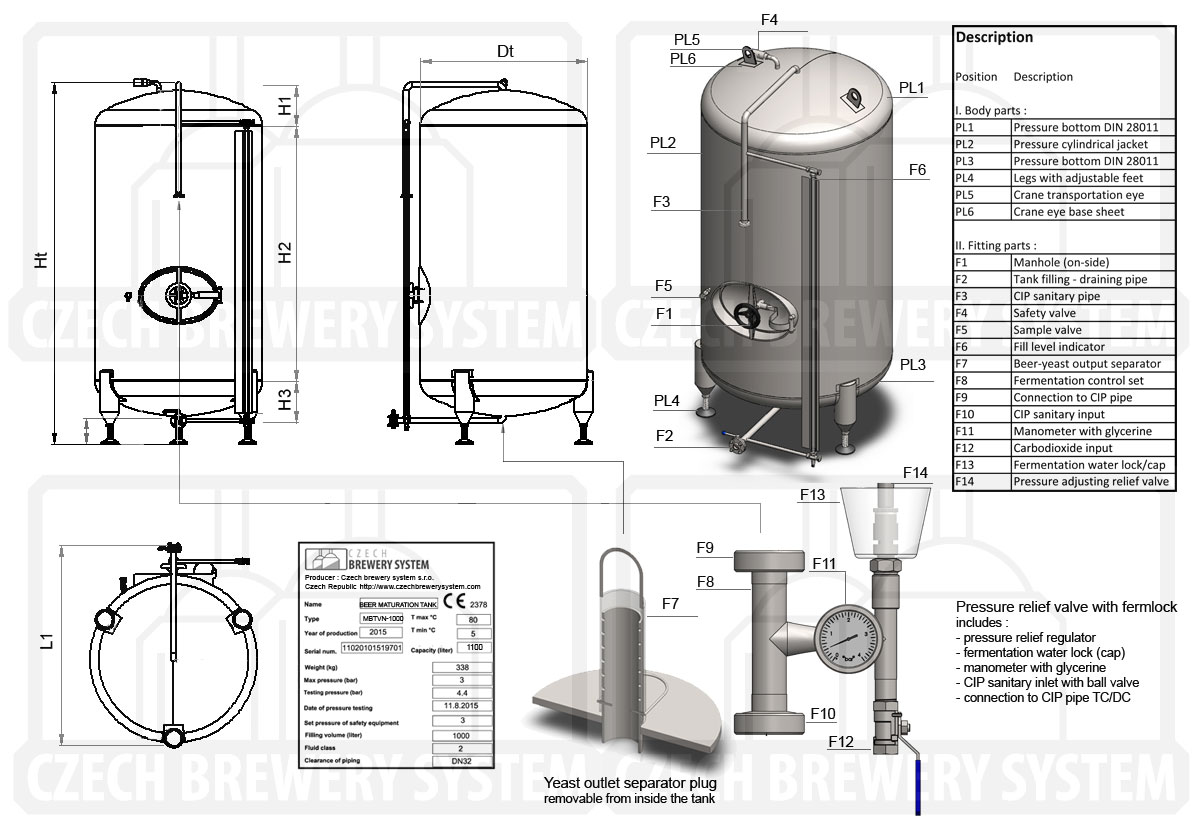

Description of the tank for beer maturation / non-insulated, vertical, cooled with air :

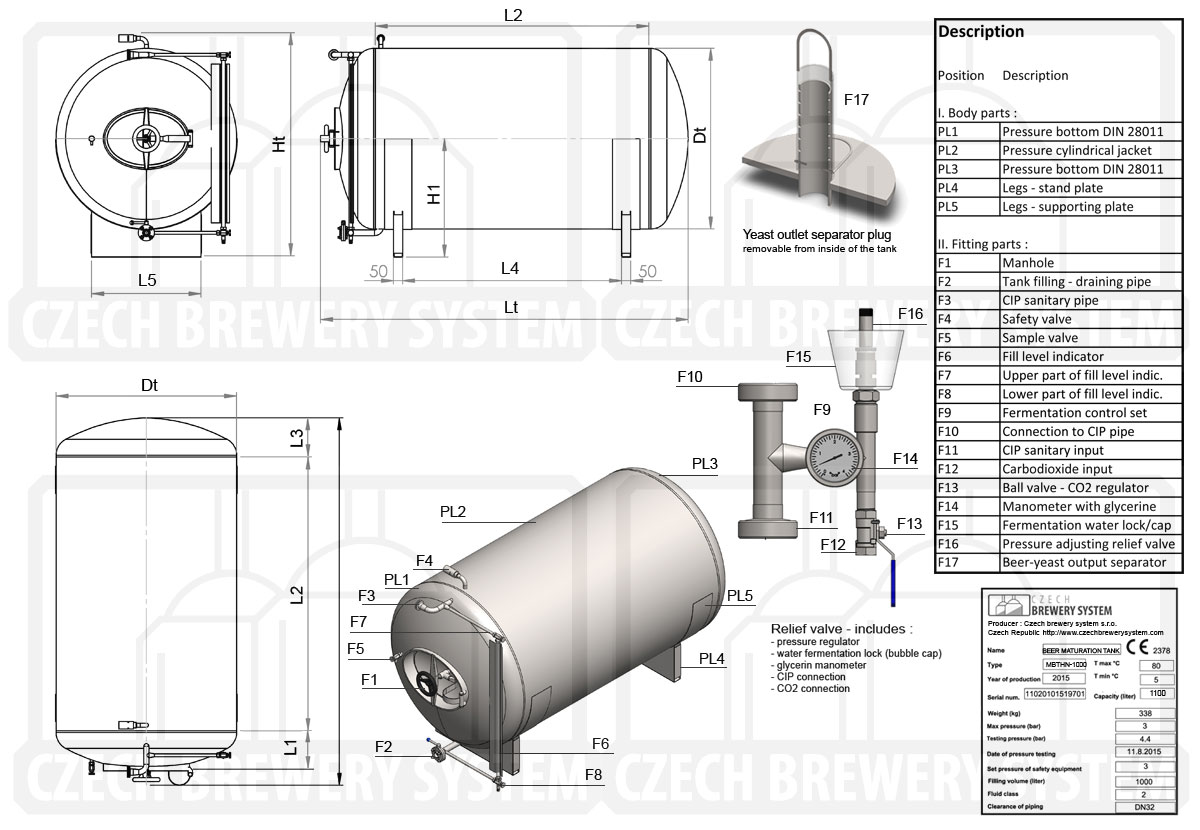

Description of the tank for beer maturation / non-insulated, horizontal, cooled with air :

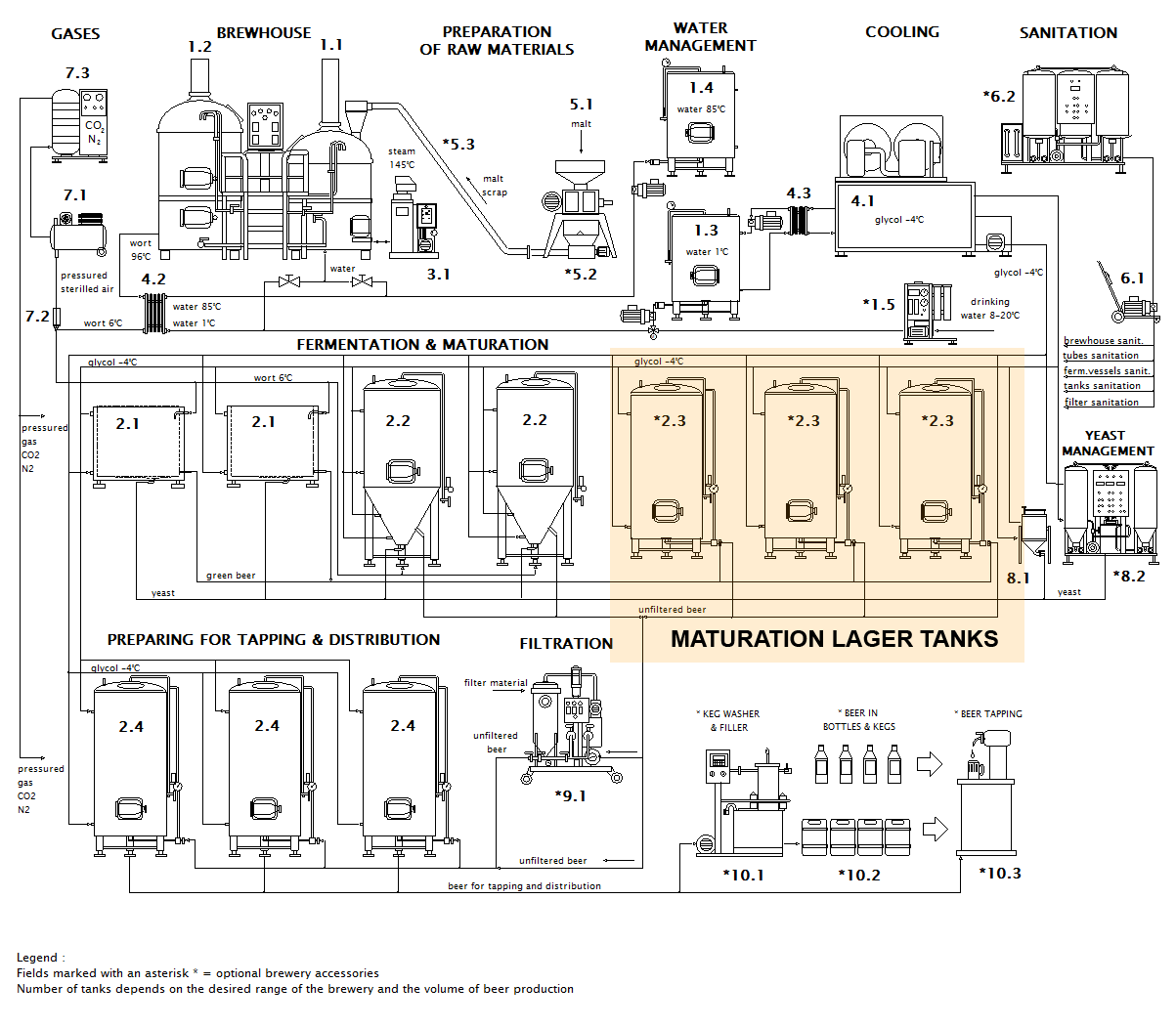

Position of the maturation tanks as fermentation equipment in a brewery :

In many breweries the pressure cylindrically-conical tanks are often used instead the cylindrical beer maturation tanks. In these universal fermenters both the main fermentation and the maturation phases of beer can take place without needs pumping beer from the primary fermentation vessel to another secondary tank. More about … cylindrically-conical fermenters

Standard equipment :

Adjustable pressure valve with a fermentation lock – a special valve that is designed to controlled fermentation and maturation of beer under required overpressure.

Adjustable pressure valve with a fermentation lock – a special valve that is designed to controlled fermentation and maturation of beer under required overpressure.- Tank draining armature with the yeast separator – a special removable short pipe that is designed to easy separation of pure beer from sedimented yeasts above a bottom of the tank.

- Cooling channels – cooling duplicators for circulating of coolant in the cooling jacket of the tank (one, two or more independent channnels according type and volume of the tank)

- PUR insulation – polyurethane insulation with thickness according to the size of the tank and the target environment (standard thickness = 50mm )

- Outer jacket of the tank of stainless steel – with the required surface finishing (standard finish = grinded surface)

- Guaranteed inner surface roughness – Ra < 0.8 μm or less (grinded surface) / Ra < 0.5 μm or less (polished surface)

- Service door (inspection manhole) – on the upper bottom of the tank or on the front of the cylindrical part of the tank, according to customer requirements (SQ = door opening to inside / HQ = door opening to outside)

- Bottom tank filling-draining armature – with a butterfly valve for filling tank, discharging of yeast and draining of full content of the tank

- Sanitizing shower – CIP spray-ball (SQ = statical / HQ = rotational) – one or more pcs

- Sanitation pipe – a multifunction pipe with a ball valve for connect of accessories like the sanitizing shower, the CIP station (for cleaning, sanitizing), the adjustable pressure valve with manometer, the carbon dioxide inlet.

- Sample valve – cleanable and sanitizable sampling cock for collection of beer samples to laboratory tests and for tasting of beer during the beer maturation process.

- Safety valve – the universal safety valve with overpressure protection (standard = 3.2 bar) and vaccum protection (0.2 bar) – only on pressure version of the tank.

- Venting valve – special valve for safety draining of the tank with protection of the tank against implosion during pumping-out of content. The valve is also designed for accurate measuring of pressure in the tank using a manometer (when the shower ball shower is blocked or filled with foam).

- Thermometer socket – welded socket for inserting of thermosensor or thermometer (available one or more pieces according type of the tank)

- Manometer – is an accessories of the adjustable pressure valve, it is made of stainless steel, with glycerine fill.

- Fill level indicator – it is cleanable and sanitizable glass pipe for visualisation of beverage level in the tank (SQ = fixed / HQ = removable)

- Transport hinges – steel welded hinges for safety transport of the tank with crane or forklift

- Adjustable feet – the tank stands on 3 or 4 legs with rubber feet for accurate nivelation of the tank on an uneven floor.

- Type label – the steel label with all parameters that are required by European Union for pressure vessels according the PED 97/23/EC standard.

- PED 97/23/EC certificate – the European certificate for the overpressure vessel + document for archiving history of the pressure vessel

Optional equipment :

- Pressure adjustable pressure valve without fermentation lock – Simplified setting mechanism for adjusting overpressure in beer serving tanks – it may be equipped with a glycerine manometer (standard range from 0 to 3 bar ) – necessary for keeping beer under pressure during all operations with the tank. The same function may be ensured by the pressure adjustable valve with the fermentation lock (usual as part of the beer maturation tank).

- Special doors – inspection manholes – secondary door with small sightglass or the full-glass door.

- Special cleaning-sanitizing showers – rotational, pulse or other special cleaning equipment for extra powerfull cleaning of the tank.

- Side or upper universal armature – for dry hopping, flotation, installation of carbonization stone etc.

- Scale for the fill level indicator – litres scale on a protect cover of the fill level indicator for visualization of the current volume content of the tank.

- Scale for the adjustable pressure valve – a scale on a adjustable pressure valve screw for indication of just required pressure in the tank (a manometer shows the current pressure)

- Temperature measuring and regulation components – we deliver more types of thermosensors, thermometers and also completelly equipped temperature control systems.

- Thermometers, thermocouples, thermoregulators – more types for installation directly on the tank or on a wall of the tank

- Automatical thermo regulation valves – for regulation the coolant flow in the cooling channels

- Thermo controller placed directly on the tank – measuring and regulation of temperature in the tank on the compact digital temperature controller placed directly on each tank

- Common control box – a system for measuring and regulation temperature in more tanks from a common switchboard cabinet that is placed on the wall of the room.

- Automatic temperature measuring and control system – compact system for full automatic control of the beer fermentation and maturation processes in more tanks.

- Carbonization candle – the special candle with a porous stone for carbonization of beverages (for example the additional saturation of beer by carbon dioxide after too short beer maturation process)

- Service ladder – for easy access to the high placed parts of the bigger tanks

- Tank filling hub – a special tool to easy separation of dirty solutions from pure product during the filling of the fermentation tank with a beverage (like wort , cider must etc)

- Stirring equipment – an engine with agitator to stirring contents of the tank. It can be mounted on the outer side of the tank jacket.

- Customizations of the tank – we can to customize each tank according to customer´s requirements – non-standard dimensions, special armatures, special surface, special design of the tank etc.

Cylindrical beer maturation tanks, air-cooled, liquid-cooled, insulated, non-insulated

According to customer requirements, we supply pressure cylindrical beer maturation tanks in these variants in terms of cooling and insulation:

1. MBTXN Cylindrical beer maturation tanks cooled by air, non-insulated

These cylindrical beer maturation tanks have the easiest construction therefore there is possible to purchase them for the lowest price. We produce these tanks in single-jacketed version without any cooling channels. Tanks have to be placed in insulated chilled room or insulated cooling box, where the space is cooled with external air cooling unit. Main advanatage is their low purchase cost. Their disadvantage is that the temperature in each tank cannot be regulated independly regardless of the other tanks. The human operating comfort is lower as well because operators work in cold and humid surroundings. The electric consumption is higher when tanks are cooled with air instead the liquid. Yet this type of tanks is most commonly used in brewery restaurants mainly due to investment savings.

These cylindrical beer maturation tanks have the easiest construction therefore there is possible to purchase them for the lowest price. We produce these tanks in single-jacketed version without any cooling channels. Tanks have to be placed in insulated chilled room or insulated cooling box, where the space is cooled with external air cooling unit. Main advanatage is their low purchase cost. Their disadvantage is that the temperature in each tank cannot be regulated independly regardless of the other tanks. The human operating comfort is lower as well because operators work in cold and humid surroundings. The electric consumption is higher when tanks are cooled with air instead the liquid. Yet this type of tanks is most commonly used in brewery restaurants mainly due to investment savings.

We offer two variations of this type beer tank :

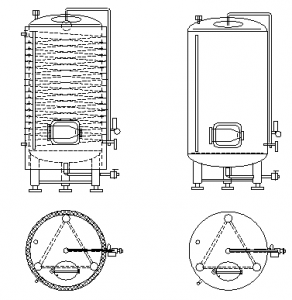

- MBTVN – cylindrical beer maturation tanks, vertical , non-insulated

- MBTHN – cylindrical beer maturation tanks, horizontal, non-insulated

>> Our offer for standard non-insulated cylindrical beer maturation tanks

2. MBTXI-S Cylindrical beer maturation tanks cooled by liquid, non-insulated

The most frequently used cylindrical beer maturation tank fermenter type is a price compromise between tanks cooled with air and insulated tanks cooled with liquid – the non-insulated beer maturation tank which is cooled by liquid. They are more expensive than tanks cooled with air but cheaper than insulated tanks cooled with liquid. These tanks include double cooling channels with the cooling liquid flows through them but the tanks do not have any insulation and any outer jacket. We recommend to place the tanks in the insulated room, where avoid the redundant heating of tanks. Their advantage is relatively low purchase cost and medium-level electric consumption of the coolers. More powerful liquid cooler is needed in comparation with insulated tanks.

The most frequently used cylindrical beer maturation tank fermenter type is a price compromise between tanks cooled with air and insulated tanks cooled with liquid – the non-insulated beer maturation tank which is cooled by liquid. They are more expensive than tanks cooled with air but cheaper than insulated tanks cooled with liquid. These tanks include double cooling channels with the cooling liquid flows through them but the tanks do not have any insulation and any outer jacket. We recommend to place the tanks in the insulated room, where avoid the redundant heating of tanks. Their advantage is relatively low purchase cost and medium-level electric consumption of the coolers. More powerful liquid cooler is needed in comparation with insulated tanks.

We offer two variations of this type beer tank :

- MLT-S Simplified cylindrical tanks for beer maturation … (simplified low pressure tanks with overpressure 1.2 bar max)

>> Our offer for simplified non-insulated cylindrical tanks for beer maturation, cooled by water

3. MBTXI Cylindrical beer maturation tanks cooled by liquid, insulated

The fully insulated cylindrical beer maturation tanks cooled with liquid are a professional solution for all restaurants keepers for whom the savings of operating costs are at the very first place. Tanks include cooling channels with the flowing cooling liquid. The tanks have a cylindrical part insulated with PUR foam. Also both bottoms of the tank can be insulated for extra surcharge. The outer jacket is covered with insulation and it creates a clean design of stainless steel tank. It is possible to place the tanks in a non-insulated room because insulation provides the protection against unwanted escape of cold from beer tanks. Their advantage is mainly their low electric consumption when the tanks are cooled, the need of the less powerful liquid cooler and high comfort for operators because people may not work in air-cooled space.

The fully insulated cylindrical beer maturation tanks cooled with liquid are a professional solution for all restaurants keepers for whom the savings of operating costs are at the very first place. Tanks include cooling channels with the flowing cooling liquid. The tanks have a cylindrical part insulated with PUR foam. Also both bottoms of the tank can be insulated for extra surcharge. The outer jacket is covered with insulation and it creates a clean design of stainless steel tank. It is possible to place the tanks in a non-insulated room because insulation provides the protection against unwanted escape of cold from beer tanks. Their advantage is mainly their low electric consumption when the tanks are cooled, the need of the less powerful liquid cooler and high comfort for operators because people may not work in air-cooled space.

We offer two variations of this type beer tank :

- MBTHI – cylindrical beer maturation tanks horizontal , insulated

- MBTVI – cylindrical beer maturation tanks vertical, insulated

>> Our offer for standard insulated cylindrical beer maturation tanks

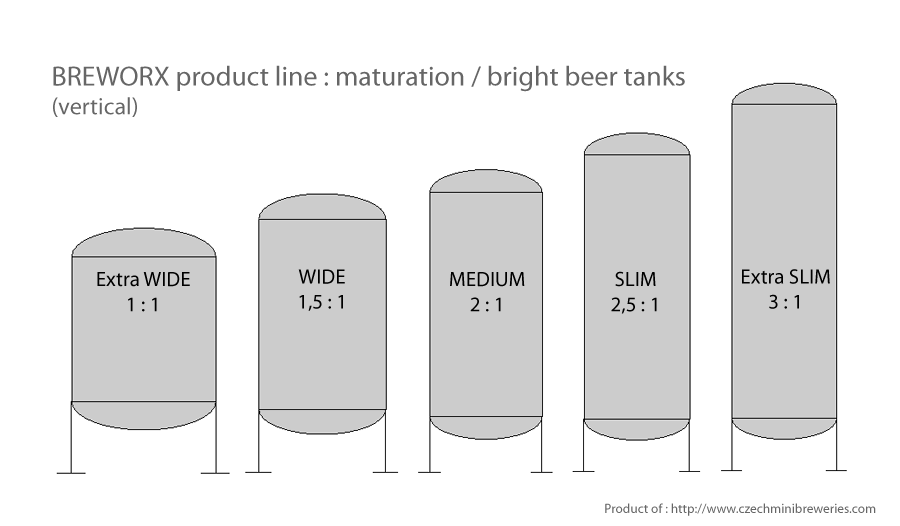

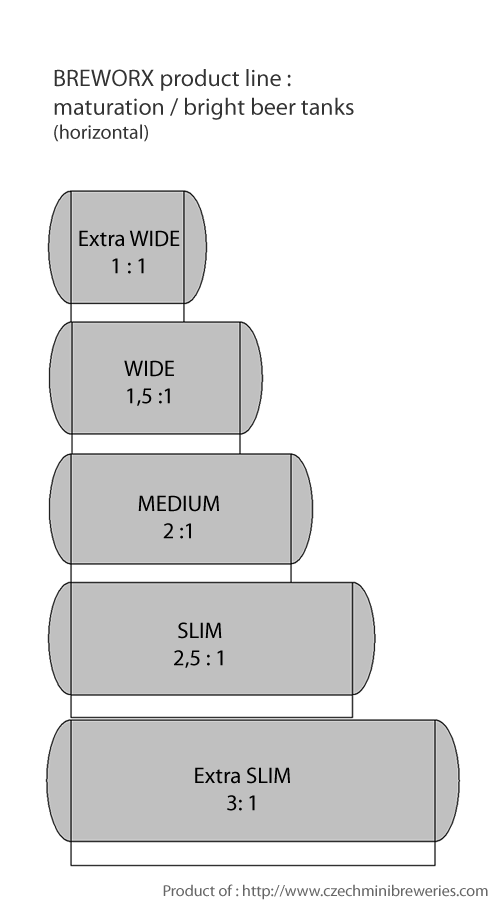

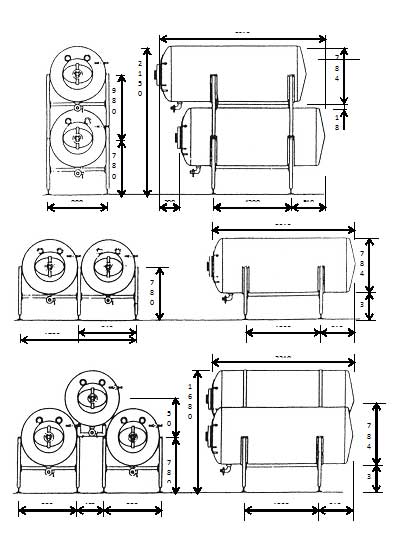

We produce pressure cylindrical beer maturation tanks with variable dimensions and orientations

We can customize the dimensions and spatial orientation of the overpressurecylindrical beer maturation tanks according to customer requirements. We produce vertical and horizontal cylindrical beer maturation tanks, with the side-to-tank ratio being selected from several variants.

1. MBTVX Cylindrical beer maturation tanks – vertical

The vertical orientation of cylindrical beer maturation tanks has a many practical advantages:

The vertical orientation of cylindrical beer maturation tanks has a many practical advantages:

Effective cleaning and sanitation of the whole tank with only one rinsing head (cost savings).

Easy manual cleaning of both inner and outer surface of the tank – usually it is possible to stand in the inside of the tank when cleaning and it is possible to walk around the tank.

Small space of floor area, effective usage of vertical room space.

Easy manipulation and access to all armatures and functional parts of the tank.

Precise tracking of product quantity in a tank using a level gauge.

We offer two variations of this type beer tank :

- MBTVN – cylindrical beer maturation tanks vertical , non-insulated

- MBTVI – cylindrical beer maturation tanks vertical, insulated

>> Our offer for standard vertical beer maturation tanks

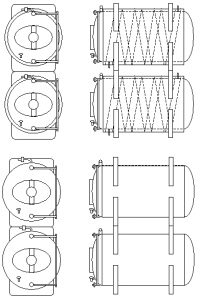

2. MBTHX Cylindrical beer maturation tanks – horizontal

The horizontal orientation of the tanks is practical in breweries with insufficient height for the location of vertical cylindrical beer maturation tanks.

The horizontal orientation of the tanks is practical in breweries with insufficient height for the location of vertical cylindrical beer maturation tanks.

Horizontal cylindrical beer maturation tanks can be positioned in several layers to maximize their number according to the available room height. The main disadvantage of horizontally oriented tanks is, in particular, poor access to hidden space between of the tanks, where is accumulated dirt, which may be the source of unwanted infections of yeast and beer. We recommend the horizontal tanks only for breweries with a really low ceiling height in the beer cellar room.

We offer two variations of this type beer tank :

- MBTHN – cylindrical beer maturation tanks horizontal , non-insulated

- MBTHI – cylindrical beer maturation tanks horizontal, insulated

>> Our offer for standard horizontal beer maturation tanks